STANDARD TYPE HORIZENTAL Z ELEVATOR

It is a machine used during transportation of agricultural products such as pulses, seeds, wheat etc.. and highly fragile industrial feedstocks from one point to another during the processing or packaging. It is preferable since it does not damage the product during transportation.

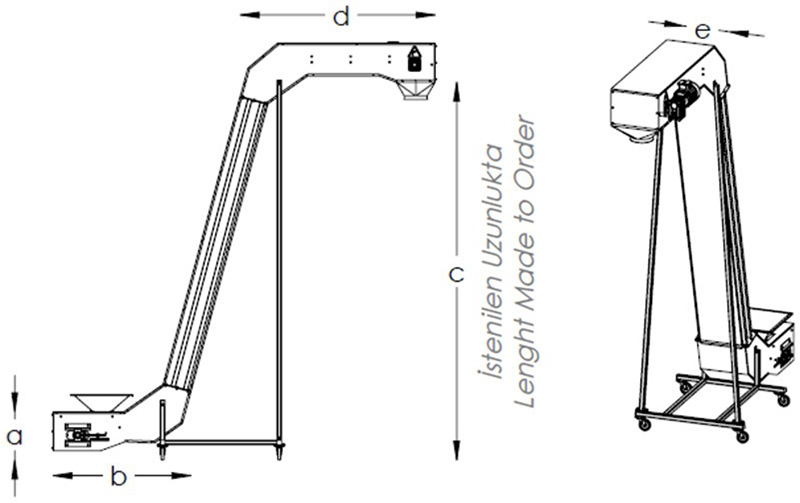

Due to its ability to carry on the horizontal and vertical axes concurrently, it provides very efficient solutions in complex production lines. Horizontal and vertical axis lengths can be manufactured in desired dimensions. It was named as "horizontal z elevator" because it was designed to increase at an angle of 75 ° to the vertical axis. The reason for being designed to move with this angle is to extend the distance taken by the horizontal axis and increase the product drawing capacity.

Working principle

Buckets designed specifically for the endless chain system running through the gears inside the machine are fixed. The product discharged into the buckets is poured in the reverse direction at the pouring point. It is generally produced along with vibrating feeders since the production process must be homogeneous. In processes with homogeneous (smooth and constant) flow, It can also be operated with collector elements.

MODEL

|

PRODUCT

CODE

|

A

mm

|

B

mm

|

C

mm

|

D

mm

|

E

mm

|

BUCKET

SIZE

|

BUCKET

TYPE

|

POWER

|

REDUCTOR

TYPE

|

AUTOMATION

|

CAPACITY

|

Standart Type

|

STYZE 350

|

1200

|

1200

1700

|

3000

|

340

|

450

|

350 mm

|

Plastic

|

0,75 KW

|

WGR

|

OPTIONAL

|

3-4 m³/s

|

Standart

Type

|

STYZE 400

|

1200

|

1200

1700

|

3000

|

340

|

525

|

450 mm

|

Plactic

|

0-75 KW

|

WGR

|

OPTIONAL

|

5-6 m³/s

|